[ad_1]

Honda R&D Co., Ltd. (Honda) and Toray Industries, Inc. (Toray) have begun a joint demonstration associated to closed-loop recycling*1 of the Nylon 6 resin*2 (“Nylon resin”) recovered from Finish-of-Life Automobiles (ELVs).

This joint demonstration is licensed by the Japanese Ministry of the Setting (MOE) as part of its mission to determine a decarbonized round economic system system*3. Honda and Toray will set up and confirm a pilot facility with a processing capability of 500 metric tons of resin per 12 months, with the goal of placing this recycling course of into sensible software by round 2027.

As evidenced by the enactment of the Plastic Useful resource Circulation Act, societal demand for the recycling of not solely beverage containers and clothes but additionally waste plastics has been rising lately in Japan. Nonetheless, till now, the remedy of automotive nylon resin waste has been restricted to the restoration and utilization of warmth vitality generated throughout incineration, as a result of technical problem of sorting, accumulating, and recycling.

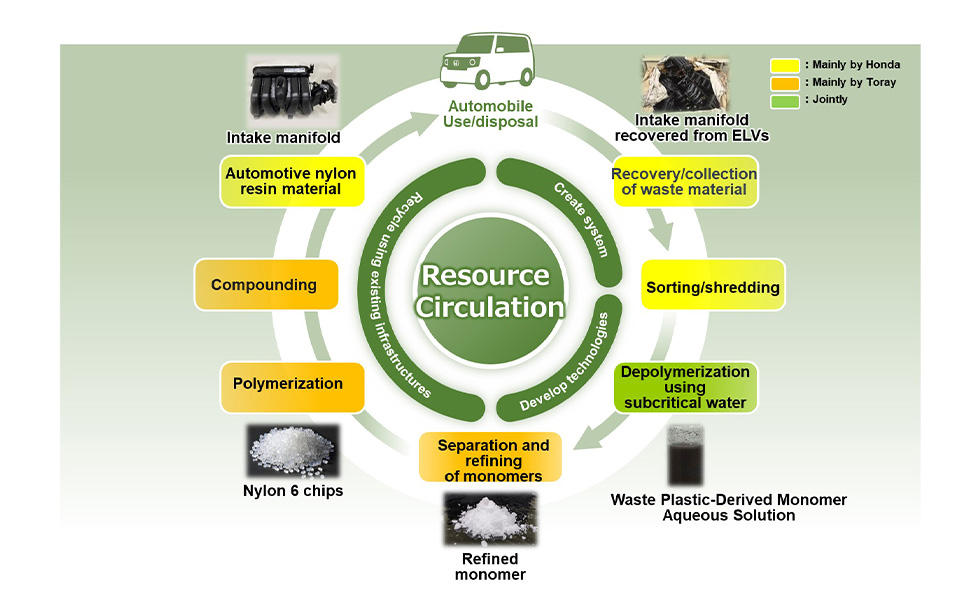

Towards this backdrop, Honda and Toray have collectively succeeded in monomerizing recovered nylon resin again to its molecular state utilizing subcritical water*4. The usage of subcritical water as a solvent has been confirmed to outcome within the recycling of nylon resin in a shorter time, with the next yield*5 and fewer environmental influence in comparison with the method utilizing typical acid catalysts. Making use of this know-how on this joint demonstration, the 2 firms will confirm the recycling of consumption manifolds recovered from ELVs in Japan and attempt to determine a closed-loop recycling course of to generate recycled materials with the equal efficiency and high quality as a virgin materials.

<The method of the closed-loop recycling to be demonstrated>

<Key options of the nylon resin closed-loop recycling know-how Honda and Toray will confirm>

- It’s doable to provide monomers, a uncooked materials for engineering plastics*6, instantly from the recyclable materials.

- This monomer manufacturing methodology which makes use of water as a solvent permits extra environmentally accountable and environment friendly monomer manufacturing, taking solely one-fifth the time, in comparison with the tactic utilizing typical acid catalysts.

This know-how is predicted to be relevant to monomerizing supplies for engineering plastics apart from nylon resin. Via this joint demonstration, the 2 firms will confirm how successfully their recycling know-how can contribute to a round economic system when utilized to a broader vary of supplies, together with non-automotive elements, similar to clothes and movie, primarily in Japan.

Honda has recognized “useful resource circulation” as one of many key instructions to give attention to to be able to future advance its mobility merchandise. Via varied partnerships and collaborations, similar to this one with Toray, Honda will proactively make the most of recycled assets and proceed striving for the conclusion of “zero environmental influence.”

*1A recycling course of the place post-consumer merchandise are recycled to produce the fabric used to provide a brand new model of the identical sort of product.

*2A kind of nylon resin Its excellence in energy, warmth resistance and chemical resistance makes Nylon 6 appropriate for automotive elements which might be usually uncovered to warmth, gasoline and automotive oils.

*3Ministry of the Setting fiscal 2023 mission to determine a decarbonized round economic system system (together with the Demonstration Venture for a Plastic Useful resource Circulation System)

*4The high-temperature and high-pressure liquid water at a temperature and strain barely under the important level of water (374 °C, 22 MPa).

*5The ratio of the amount of goal substance really obtained in relation to the theoretically anticipated amount when extracting the goal substance from the uncooked materials substance in a chemical response.

*6Plastics with glorious mechanical energy, warmth resistance and abrasion resistance, extensively used for elements of equipment, vehicles, digital tools, and different merchandise.

SOURCE: Honda

[ad_2]