[ad_1]

Sponsored by TTI.

Electrical automobiles are set to turn out to be the idea of future transport, and the transition is going on far more shortly than imagined. In current months, EV uptake has elevated dramatically, with the inflated oil costs at the moment being skilled more likely to speed up adoption nonetheless additional.

EV registrations are actually getting shut to 1 million monthly worldwide. They’ve already overtaken new diesel automobile gross sales (January 2022). Market analysts now count on them to exceed gross sales for all new inner combustion engine (ICE) automobiles inside the 2025 timeframe – far sooner than their earlier projections had outlined (the place this was not forecast to occur earlier than 2030).

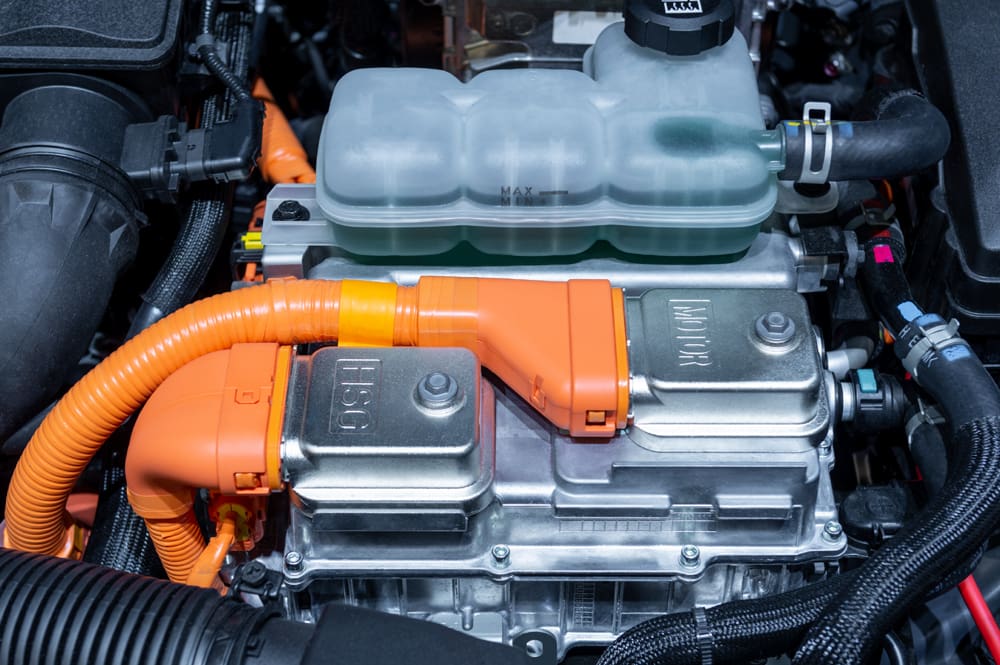

EVs are, in precept, far much less advanced than conventional ICEs, because of the elimination of the 1000’s of mechanical parts in an engine and all of the supporting mechanical subsystems. Nevertheless, they nonetheless current an entire new set of engineering challenges. Specifically, extra detailed monitoring of key features and parameters is required to realize the excessive efficiency and effectivity wanted to keep up protected operation.

Elevating powertrain voltages

Suppose an EV is operating at most effectivity ranges. In that case, the power saved inside the battery will last more and ship an prolonged vary, thus the flexibility to journey a major distance between recharges. To boost effectivity and allow shorter recharging intervals, automotive producers are growing the voltages utilized in EV powertrain architectures from 400V to 800V. After all, whereas doing this, it’s important to keep up automobile and driver security.

Ongoing EV battery evolution

Primarily based on Li-Ion chemistry, the battery pack is central to driving the traction motor. Nevertheless, given the potential for broken, defective or ageing cells to overheat, the working circumstances of the pack are repeatedly monitored at a mobile stage. Situation monitoring is completed by the battery administration system (BMS).

Automotive producers and their battery provide companions are all the time trying to improve the cell density of their battery packs to ship larger power storage capability from smaller type components. Nevertheless, this places additional pressure on the cells, so the necessity for the BMS to have the ability to entry detailed information turns into much more important.

By utilizing this information, the BMS won’t solely be capable of mitigate the risks of thermal runaway, however it can additionally be capable of stability the load throughout all of the totally different cells inside a battery pack. Thus, the cells performing poorer than their neighboring ones won’t be subjected to dangerous stresses. The result’s that cost is best distributed throughout the battery and can final significantly longer, avoiding undesirable alternative prices.

Attributes defining interconnect choice

The protection-critical nature of EV monitoring exercise signifies that information switch have to be carried out at excessive pace, with low latency and warranted reliability. Subsequently, connectors that assist the information charges outlined by the newest in-vehicle networking protocols must be chosen. Superior sign integrity additionally must be attained, even with potential sources of electromagnetic interference (EMI) close by.

One other facet to be thought-about is the space-constrained surroundings. Specified connectors must be compact, whereas nonetheless that includes a excessive variety of contacts, and be rugged sufficient to deal with shocks, vibrations, and excessive temperatures.

Because the bills of EVs can typically be a priority for potential automobile consumers, conserving the general bill-of-materials prices down is a excessive precedence for automotive producers. Subsequently, the connectors should have all of the described options and be positioned at acceptable worth factors.

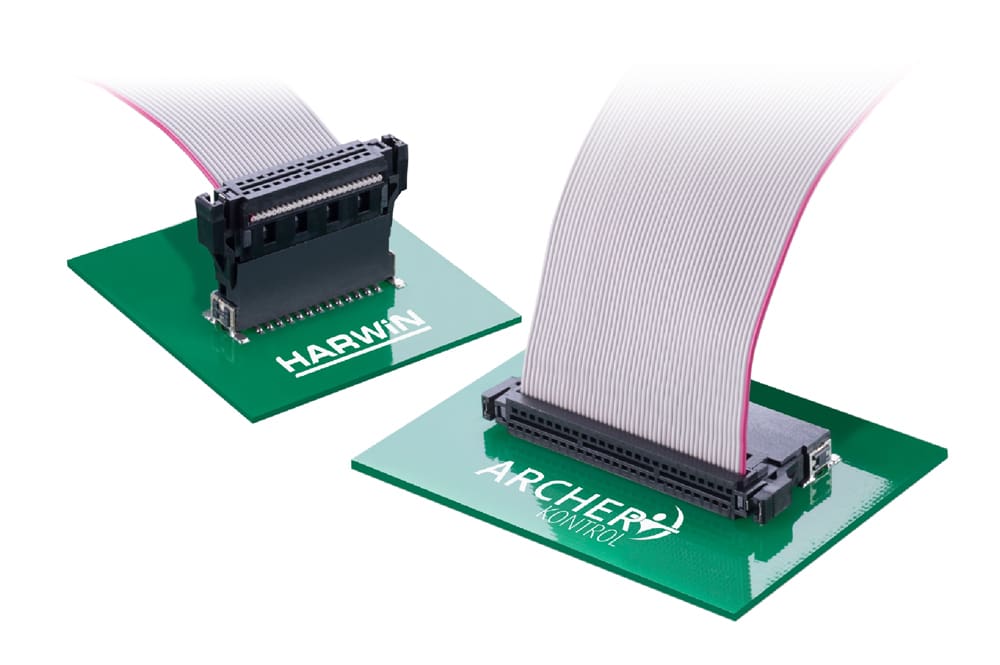

Interconnects optimized for EV information acquisition

Harwin’s Archer Kontrol board-to-board connectors are utilized in numerous EV fashions for powertrain monitoring and diagnostic duties. These 1.27mm pitch connectors have compact type components and may be provided in vertical or horizontal orientations, so that they take up minimal house inside the system design. Additionally, a stacking peak from 8mm to 20mm is out there, giving producers larger flexibility.

Consistent with the necessities of automotive purposes’ Ethernet community infrastructure, 3Gbps information charges are supported. They will address 125°C temperatures, 20G vibrations, and 50G shocks. The phosphor bronze contacts with a gold/tin end provide extended sturdiness. These contacts are embedded into sturdy plastic housings which have UL94V-0 anti-flammability scores.

Shrouding the Archer Kontrol connectors protects their contacts from the danger of harm. Accessible on request are off-the shelf cable assemblies in both 150mm or 300mm lengths, and customized cabling is feasible. Latches are included for delivering further pressure aid. In inventory and out there from TTI.

Future generations of EV powertrains will rely upon increased efficiency information acquisition capabilities. The potential of real-time communications between all of the totally different powertrain subsystems, from the battery packs to the onboard chargers and DC/DC converters, will lead to increased effectivity and larger total security. It permits producers to achieve a aggressive benefit, whereas safeguarding their model status.

[ad_2]