[ad_1]

The M10 BMW engine—BMW’s longest-running energy plant—made its debut on the 1961 Frankfurt Motor Present alongside the all-new BMW 1500 ‘Neue Klasse’ (New Class) sedan. The 1500 was a brand new and really trendy automobile with neat styling, entrance disc brakes, all-independent suspension with rear semi-trailing arms, and underneath the hood, that freshly minted SOHC M10 engine.

The Engineering

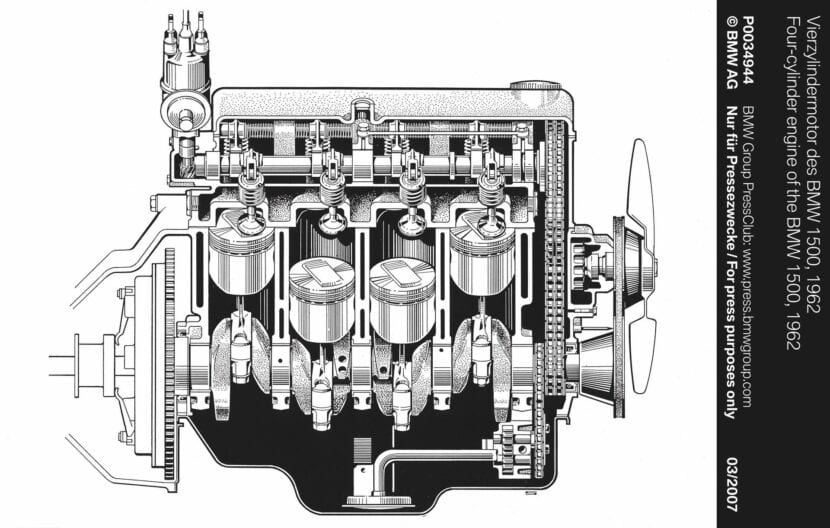

All new, the M10’s iron block (crankcase) was extremely robust with massive 82 mm bores, whereas the 5 crankshaft principal bearings had been set excessive up for further rigidity, versus being on the block centerline. The crankshaft itself was comprised of solid metal with 2-inch rod bearings and large counterweights. Cast metal connecting rods with studs and nuts for the rod finish caps moderately than plain bolts had been used together with solid alloy pistons. Bore and stroke had been 82 mm by 71 mm to present a capability of 1499 cc, and energy was rated at 80 bhp. It exhibits how far forward of the pack it was in comparison with the 45-odd bhp of a Volkswagen 1500 unit.

The oil pump bolted to the entrance of the block and ran from a separate brief chain from a sprocket on the top of the crankshaft behind the timing chain sprocket. A pressed metal oil pan was used on these early vehicles, with a two-piece alloy/metal pan coming afterward. The crossflow cylinder head was comprised of alloy with formed hemispherical combustion chambers, and it had massive valves for its time, 39 mm inlets and 35 mm exhausts, which crammed the massive bores.

Due to the working angle of the valves, BMW may have used both two camshafts like an Alfa, however to scale back friction and weight, they used a single camshaft with rockers on both aspect. The camshaft was pushed by a duplex (twin row) chain from the crankshaft with a plastic rail on the inlet aspect and a spring-tensioned sprocket on the exhaust aspect—this was revised earlier than lengthy. The cam lobes had been lubricated by a hole spray bar with appropriate oil holes squirting pressurized oil on the hole between two lobes to lubricate each lobes.

The oil provide got here from two galleries and two banjo bolts that distributed the oil provide into the spray bar. Rocker shafts had been fitted into the pinnacle on both aspect of the cam with alloy rocker arms with metal suggestions for the carrying floor plus metal eccentric adjusters that operated on the valves. These eccentrics used a ten mm nut and metal bolt and may very well be adjusted for the proper valve clearance. A forged alloy cam cowl with studs and nuts was used.

The distributor was fitted behind the pinnacle and ran from a gear on the camshaft, whereas fuelling was by a single Solex 36 PDSI single choke carburetor provided by a mechanical pump bolted to the aspect of the cylinder head, operated by a lobe on the cam. The cooling system was unconventional, with a distant thermostat linking the hoses from the highest and backside of the radiator and the water pump.

The M10 was a really powerful and dependable engine suited to the high-speed operation of Autobahns, though there have been just a few cases of connecting rod breakage of the primary batch of engines, quickly rectified.

First Technical Revision

The primary revision to the M10 was a capability improve to 1800 cc in August/September 1963, achieved by a rise in bore dimension to 84 mm and the stroke to 80 mm giving 1773 cc. Energy output was now 90 bhp with a single 38 PDSI single choke Solex carb—once more, making a mockery of some homegrown engines.

The 1600 changed the 1500 for 1964, and its 1573 cc capability was achieved by utilizing the 1500’s crank within the 1800 block. At this level, BMW changed the unique tensioner sprocket for the timing chain with a curved nylon-lined blade that proved way more dependable. The dual carburetor 1800 Ti and 1800 TiSa vehicles additionally arrived in ’64.

The Ti engine gained greater valves (42 mm inlet, and 38 mm exhausts on later vehicles) plus a better elevate and longer length cam and a better compression ratio. With a pair of 40PHH Solex carbs, energy was now an actual DIN-rated 110 bhp. The 1800TiSa was then given a good increased compression ratio of 10.5:1 plus greater 45DCOE Weber carbs to ship 130 bhp.

BMW launched the Karmann-built 2000C Coupe in 1965, and with it got here a brand new 2-liter engine. The bore dimension was elevated to 89 mm, retaining the 80 mm stroke of the 1800 to present 1990 cc. The 2000C (all automatics) had a single 40 PDSI Solex carb to present 100 bhp with an 8.5:1 compression ratio, while the CS Coupe had twin Solex 40 PHH carbs to present 120 bhp with a 9.3:1 compression. Each 2-liter engines had the larger 42 mm and 38 mm inlet and exhaust valves and had been used a yr later within the 1966 2000 saloon (single carb) and 2000 Ti (twin carb).

To scale back manufacturing prices, the 1800 engine was revised round this time with a capability change from 1773 cc to 1766 cc, and BMW did this by combining the 2000’s 89 mm bore with the 71 mm crank from the 1600.

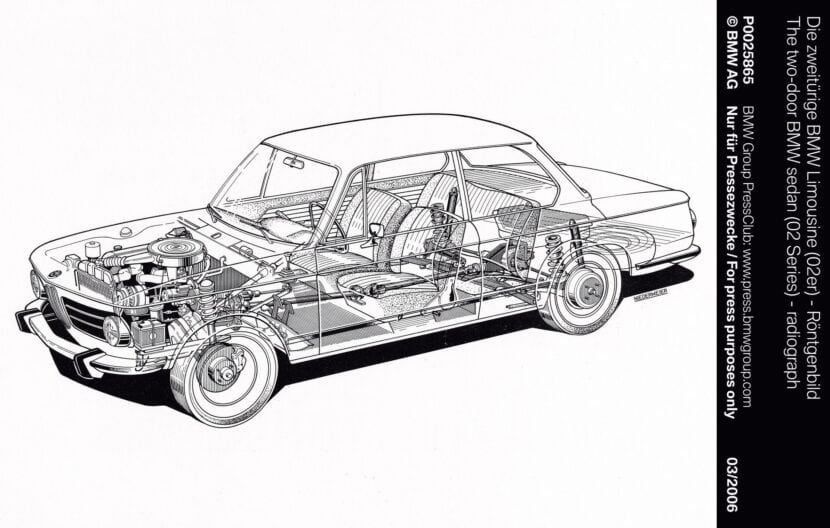

The even greater information for 1966 was the 2-door BMW 1600 in addition to a 1600Ti with 110 bhp in late 1967—and this was successfully changed in 1968 by the legendary 2002. This hotshot was shortly bettered by a 120 bhp Ti model. Extra was to return, although.

A 130 bhp gas injection model of the 2000 engine arrived in 1969. Fitted to the 2002Tii from 1971 and the 1969 2000Tii, the Tii used mechanical Kugelfischer gas injection that required a revised cylinder head and a ten:1 compression ratio for actually electrical efficiency of the time.

Used In The E12 5 Collection

In 1972, the brand new E12 5 Collection arrived with 520 and 520i variations. The M10 was revised with a brand new ‘triple hemi’ cylinder head chamber design and reshaped ports from the M30 with new matching pistons and new carburetors for the 520. These had been a pair of Stromberg 175 CDET carburetors with the 520i utilizing the present Tii Kugelfischer injection. The 2002 went to the brand new E12 engines however with a brand new twin choke Solex 32/32DIDTA carburetor.

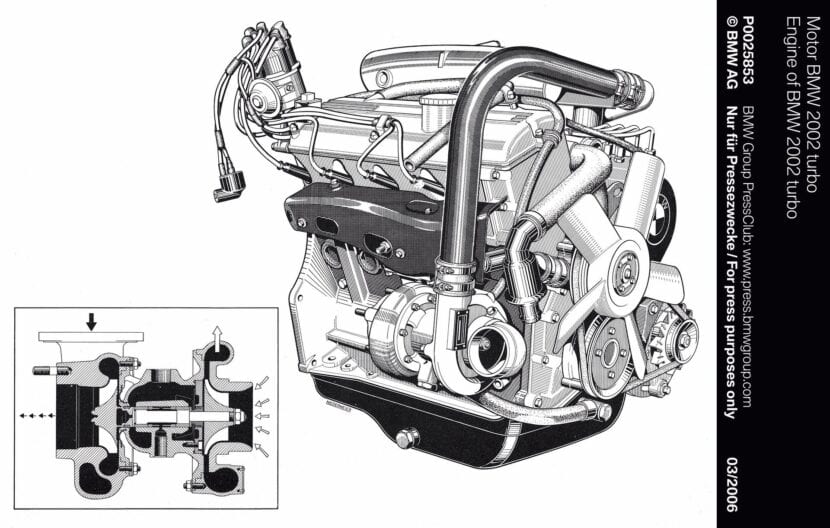

The BMW 2002 TURBO

The 2002 Turbo was the primary European turbo highway automobile, going into manufacturing in July 1973. Primarily based on the 2002 Tii unit, it had a really low 6.9:1 compression and a KKK turbocharger with a slide throttle moderately than a regular butterfly-type throttle. Giving 170 bhp at 5800 rpm with 180 nm of torque, the Turbo required ability to get the most effective from it. Turbo manufacturing resulted in 1974 after solely 1672 vehicles had been constructed, due to the gas disaster and a few social commentary within the German parliament.

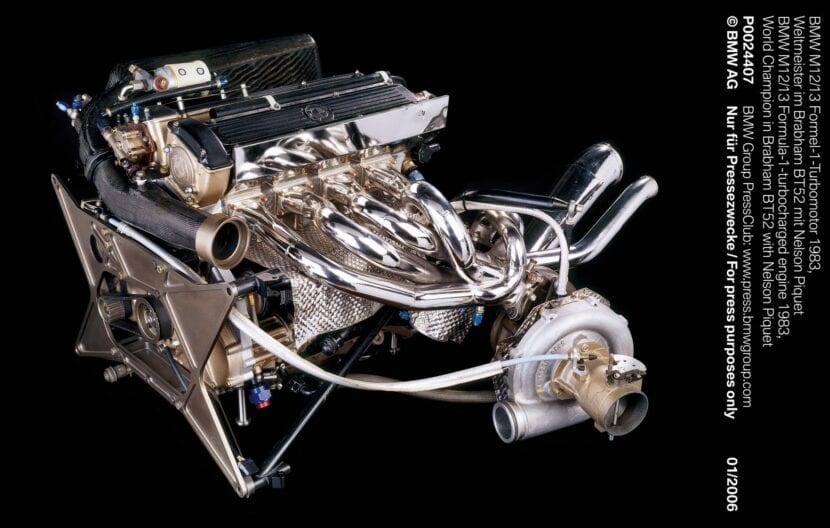

M12 Engines For Components 1

BMW constructed plenty of M12 turbocharged 1.5-litre engines for Components 1 within the mid-eighties that gave 800 bhp in qualifying and 650 bhp for racing. This rose to 1100 bhp qualifying bhp by 1985 and gave Nelson Piquet the 1983 World Championship in an M12 powered Brabham. These M12 had been constructed from extremely modified M10 blocks, secondhand excessive mileage ones because of the lack of casting stresses.

The 2002 was changed by the brand new E21 3 Collection in 1975. The cylinder head and piston designs had been once more revised together with the carburation. The 316, 318, and 320 used the present twin choke Solex 32/32DIDTA, while the 320i used Bosch Ok Jetronic injection, changing Kugelfischer for financial system and emissions with these new M10 engines going into the BMW 518 and 520 / 520i fashions from September 1975.

Changed By M60/M20

For September 1977, the 2-liter M10 was changed by an all-new 2-liter six-cylinder engine—the M60/M20. The 1600 and 1800 M10 continued, and in September 1980, the Duplex timing chain was changed by a Simplex chain, and the drive gear on the again of the cam was modified in order that the distributor now ran the opposite manner. Fuelling was now by a brand new Pierburg twin choke 2B4 carb, and digital ignition was additionally used.

A 1.8 liter unit with Ok Jet arrived for the LHD solely E21 318i and E28 518i, and these identical items had been used within the 1982 E30 316 (1766 cc) and 318i fashions. Ok Jet was on its manner out, nonetheless, and in September 1983, it was changed by Bosch LE Jetronic gas injection. The 316 and 518 had been fitted with the Solex Pierburg 2BE ECU-controlled carburettor—a lot maligned, however not practically sufficient. Energy outputs had been 90 bhp and 105 bhp respectively, and while that was not an on-paper advance on the unique Neue Klasse engines, they had been higher on gas and met all-important emissions rules.

The M10’s alternative was already within the remaining phases of design. That engine was the brand new M40 launched in September 1987 for the revised E30 318i—as an engine, it was lighter, extra highly effective, and much better on gas. The 316 used the carb M10 till July 1988, with the E28 518i manufacturing ending in December 1987. That signalled the top of the M10 manufacturing after 25 years and a hyperlink with the previous gone.

Strengths and Weaknesses

Deal with it nicely, and an M10 will do nicely over 100,000 miles. If uncared for, it’s not so good. Valve information put on is frequent, resulting in top-end noise and blue smoke, and common oil modifications forestall a variety of that. Cam sprockets on the single-row chain engines can put on badly however are simply changed. Camshaft put on is brought on by not checking and cleansing the oil spray bar holes and making certain that the banjo bolts are tight.

The spray bar could be rotated in its saddles as soon as the banjos are out, and the oil provide holes very barely enlarged with a small drill to extend oil provide and stop blocking. BMW sells thread-locked banjo bolts for the M10 and M30 which have a barely totally different thread pitch to scale back the probabilities of them working free.

Don’t threadlock them your self as a result of the thread lock fluid will congeal within the centre of the banjo, ravenous the cam lobes of oil. As on the M30, the M10 spray bar solely matches a method, and when you match it the improper manner round, it’s going to solely lubricate 4 cam lobes. Common valve lash adjustment is vital, but when the rocker pads are worn down, chances are you’ll want oversize eccentrics. Cylinder head corrosion is probably going if the antifreeze isn’t changed commonly, but when it’s essential exchange it, it should be with the proper sort—121, E12, or E21 casting varieties relying on the yr of manufacture.

An oil mild that takes ages to exit generally is a knackered rubber O-ring on the oil provide pipe that provides oil from the pump to the entrance of the block—an inexpensive half however an annoying job to interchange.

Outdated Pierburg carbs are typically a ache and are greatest changed by both a brand new Weber conversion package such because the 32/36. Bosch Ok Jetronic and LE Jetronic programs are each good and dependable—Ok Jetronic wants servicing and organising correctly, and the principle LE Jetronic weak spot is the 7-pin relay for the gas pump and injectors taking part in up.

Which Engine, Which Automobile?

- M115 – 1500 saloon 1499 cc

- M116 – 1600 vehicles till 1975, 1600 saloon, 1600 Coupe, 1602.

- M118 – 1800 saloon and 1802 till 1972, 1776 cc.

- M17, M05, M64, M15 – 1990 cc items from 1965 to 1975. 2000 saloon and 2002, 2000 C and CS Coupe, 520 and 520i.

- M10 – All engines from late 1975 and E21 – 316, 318, 318i, 320, 320i, 518, 518i

- M10 B18 – 1980 onwards E21 and E30 318, 318i, 518, and 518i E12 and E28

[ad_2]