[ad_1]

- Altering its course, Toyota has introduced heavy investments in EV manufacturing, together with three new batteries and completely reworked manufacturing strains.

- Strong-state batteries in addition to NCM Monopolar know-how with a claimed 621 miles of vary make up the way forward for Toyota’s BEVs.

- Within the footsteps of Tesla, Toyota will make use of giga casting in addition to autonomous manufacturing strains abroad, whereas the corporate concurrently builds a North American battery analysis facility in Michigan.

Toyota hasn’t precisely jumped on the electrical automobile bandwagon. With one devoted EV crossover in the marketplace and some new hybrid fashions, it is loosely maintaining with broad trade requirements whereas remaining wedded to the hybrid sector it pioneered. The truth is, the model misplaced its former CEO and public EV skeptic, Akio Toyoda, earlier this yr in a company restructuring targeted on electrification, changing Toyoda with former Lexus branding officer Koji Sato.

The months since Sato’s appointment have been markedly completely different, as Toyota softens its EV stance and even hints at an impending new electrical structure. However Toyota is taking it one step additional this week, confirming an overhaul of its electric-vehicle manufacturing and elements processes.

Future Battery That Can Quick-Cost in 20 Minutes

Unveiling a type of know-how highway map, Toyota confirms it should launch a extra sturdy, energy-dense nickel cobalt manganese lithium-ion battery by 2026, with 621 miles of vary and a fast-charge time of 20 minutes. These bZ4x-adjacent NCM batteries will likely be reserved for efficiency autos or high-end luxurious fashions, although Toyota has a plan for its lower-end items as properly.

Utilizing the bipolar construction battery (discovered within the Japanese-market Aqua and Crown hybrid autos), Toyota will increase this LFP know-how to new BEV fashions, with the corporate claiming a 20 % enhance in cruising vary and a 40% discount in price in contrast to the present bZ4x.

EV lovers can even anticipate a high-performance model of Ni-series bipolar lithium-ion batteries, indicating the potential for low-cost, high-performance EVs to come back from Toyota. These batteries will characteristic a high-nickel cathode, rising vary by 10 % whereas decreasing prices 10 %, and are set for sensible use by 2028.

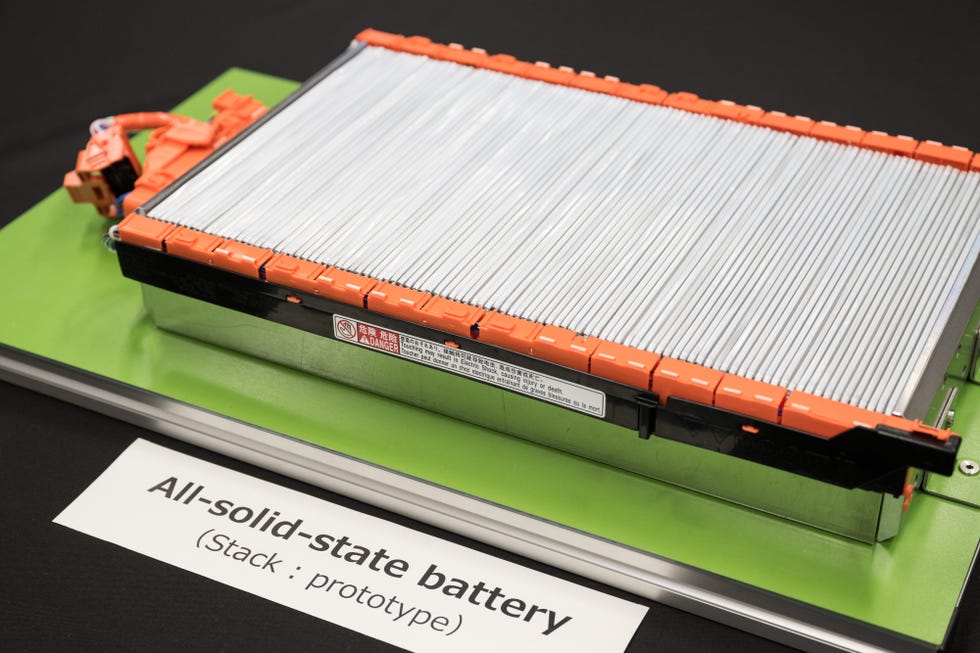

“Breakthrough” Making Strong-State Batteries Doable

Such developments are already within the works, Toyota says, however innovating past the close to future is important, firm executives mentioned. And Toyota sees solid-state batteries as undoubtedly the best way ahead, in line with its EV blueprint. The corporate is accelerating its growth of solid-state batteries largely because of “a technological breakthrough that overcomes the longstanding problem of battery sturdiness,” but in addition as a result of it estimates vary increasing some 20 % with solid-state batteries.

All of those percentages are arduous to quantify after they’re stacked on prime of one another and the corporate offers examples of enhancements with none arduous numbers. Even so, it indicators that Toyota is properly conscious of how shortly it must increase its EV attain.

So as to take action, Toyota might want to re-develop and increase its manufacturing services, from a chassis and battery standpoint. Citing elevated profitability, the corporate plans to make use of giga-casting know-how (high-pressure aluminum die-casting machines) for its future EV platforms, lowering the sheer quantity of sheetmetal elements. This manufacturing method has actually labored for Tesla, regardless of early-model manufacturing high quality points.

Automated Mass Manufacturing

Toyota says it’s ruling out the conveyor model of manufacturing for its future EV chassis, as a substitute counting on a self-propelling meeting line. This method will largely automate the method, permitting mass-produced fashions to maneuver from course of to course of independently and creating extra mannequin flexibility at every plant. Notably, Toyota says this method will considerably scale back the employees wanted for manufacturing.

In tandem with this week’s information, Toyota additionally says it’s creating a brand new battery analysis facility in Michigan. Investing $50 million, the Japanese model will assemble a North American R&D headquarters in York Township close to Ann Arbor, particularly specializing in battery analysis.

Given the present state of Inflation Discount Act tax credit score provisions, establishing manufacturing roots in North America (a battery plant in North Carolina and three-row electrical SUV meeting in Kentucky) is a no brainer. However Toyota says the R&D facility can be supposed to assist serve North American customers higher.

Taking a Shut Have a look at Individuals’ Wants

Driving wants and charging habits fluctuate tremendously even from state to state, however the American method to electrical autos has, to date, been targeted on a stability of long-range and excessive efficiency. For Toyota, understanding these nuances will likely be important to producing a aggressive product. And the power to research U.S. charging infrastructure firsthand will play a big half within the firm’s regional growth course of, the discharge explains.

Toyota’s method to EVs is shifting shortly however remnants of the earlier company tradition stay, as Toyota devoted a good portion of its presentation to hydrogen and e-fuels. Whereas its method to fuel-cell electrical autos and hydrogen primarily hinges on industrial autos, Toyota is becoming a member of the likes of European producers comparable to Porsche in exploring carbon-neutral biofuels.

Trialing hydrogen, artificial fuels, and bioethanol fuels from renewable power sources, Toyota says sure international locations or areas the place electrical energy calls for are difficult, comparable to Brazil or India, could be prime for e-fuel know-how.

In the end, echoing the corporate’s long-held speaking level, the future-looking report says Toyota needs to deploy the appropriate automobile in the appropriate place on the proper time. For a model that has been the world’s top-selling automaker for 3 straight years, this is not stunning, however Toyota will want greater than improved manufacturing and higher batteries to promote EVs. Particularly within the US, the stability wanted will likely be between inexpensive prices and inherent pleasure.

Affiliate Editor

A New York transplant hailing from the Pacific Northwest, Emmet White has a ardour for something that goes: vehicles, bicycles, planes, and bikes. After studying to experience at 17, Emmet labored within the motorbike trade earlier than becoming a member of Autoweek in 2022. The woes of alternate aspect parking have stored his fleet average, with a 2014 Volkswagen Jetta GLI and a 2003 Honda Nighthawk 750 avenue parked in his South Brooklyn neighborhood.

[ad_2]