[ad_1]

Aspen Aerogels’ cutting-edge supplies shield in opposition to thermal runaway

Thermal runaway happens inside a battery cell by a fault, a crash state of affairs or another defect that causes the cell to launch thermal vitality by chemical reactions. That thermal vitality will increase the temperature of the cell, the elevated temperature drives quicker kinetics, and extra warmth is launched, additional driving up the temperature.

Ultimately, you will get to a tipping level and, primarily, the cell catches on hearth. Thermal propagation happens when that first cell in thermal runaway causes its neighbors to additionally tip over into thermal runaway, which then spills over into the cells subsequent to them.

Talking on the latest Charged Digital Convention on EV Engineering, John Williams, Vice President of Technical Providers at Aspen Aerogels, gave a wonderful overview of cutting-edge methods to delay or stop thermal propagation situations.

MORE: Don’t miss John Williams’ subsequent webinar on April 19, 2023:

Balancing Inner Forces Inside An EV Battery Module Or Pack

Security requirements

First, a bit background. In China, the usual for thermal propagation delay is 5 minutes, defined Williams. What which means is that, from the second of detection of a hazardous scenario within the battery pack, you have to have a five-minute delay earlier than there’s a harmful scenario within the passenger compartment. These 5 minutes permits the driving force to discover a place to park, exit the car, and get a secure distance away.

“A five-minute thermal propagation delay is actually the desk stakes now for producers of electrical autos.”

“A five-minute thermal propagation delay is actually the desk stakes now for producers of electrical autos,” mentioned Williams. “As electrical autos change into extra frequent, that 5 minutes will virtually definitely ratchet as much as longer durations till, ultimately, we might attain the promised land of getting no thermal propagation in any respect.”

The final word aim is that one cell can go into thermal runaway and that’s it. It is going to be a upkeep occasion and never a security occasion. However we’re not there but, and Williams defined why.

The physics of thermal propagation

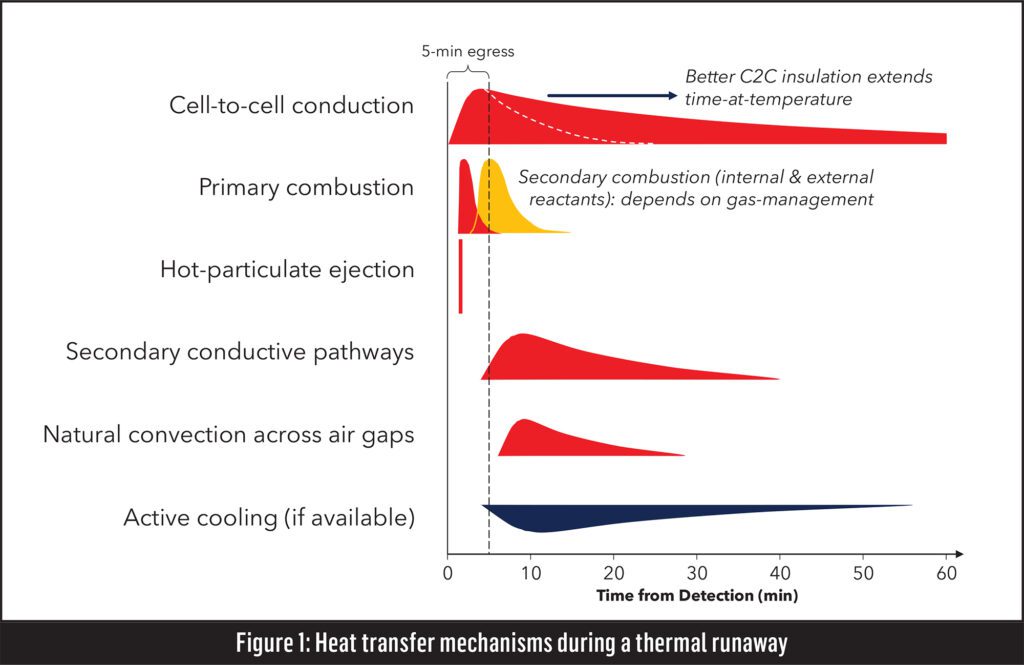

The physics of thermal propagation contain a number of pathways for warmth to switch from a cell in runaway to its neighbors, Determine 1. The primary and most necessary is cell-to-cell conduction, and Williams is an knowledgeable on this explicit pathway. Aspen Aerogels manufactures a barrier materials, referred to as PyroThin, designed to stop cell-to-cell conduction. However that’s not the one thermal pathway.

There may be additionally gasoline launch, each major combustion, through which the reactants come from inside the cell, and secondary combustion, through which the gas contained in the cell reacts with the exterior surroundings. These gasoline flows and reactions drive a whole lot of the behaviors inside a pack throughout a thermal propagation occasion. There are additionally sizzling particulates being ejected through the preliminary part of the thermal runaway. There are secondary conductive pathways, resembling busbars, cooling plates and structural interconnects between cells. These are primarily thermal bridges—conductive pathways round a cell-to-cell barrier. Additionally, warmth could also be transferred by pure convection throughout air gaps that permit sizzling gases to unfold all through the battery pack.

“Energetic cooling can assist draw down the vitality of a cell in thermal runaway,” defined Williams, “though many instances you may’t rely on it, particularly after a crash state of affairs.”

Thermal and mechanical limitations

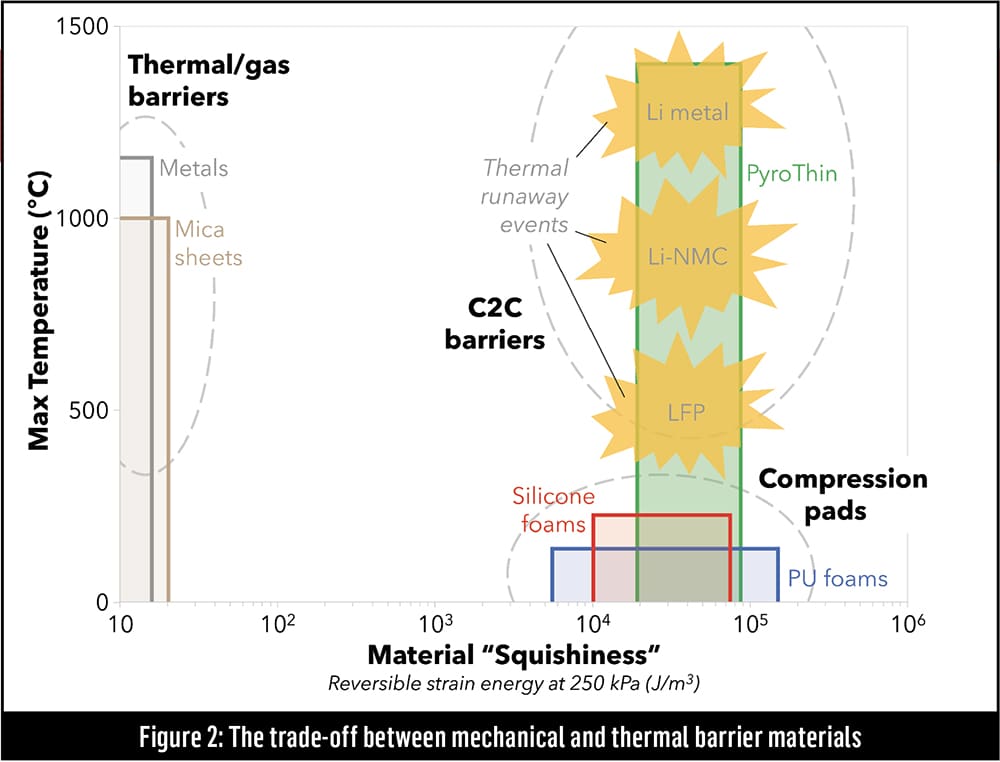

A thermal barrier materials between the cells can scale back warmth switch by cell-to-cell conduction. Obstacles in prismatic and pouch packages serve two functions: mechanical and thermal. The best barrier acts as each a mechanical compression pad and a thermal insulator, however there’s a trade-off: supplies that make superb compression pads usually present little thermal resistance, and people who act nearly as good thermal and gasoline limitations are usually too stiff to function compression pads.

The best barrier acts as each a mechanical compression pad and a thermal insulator, however there’s a trade-off: supplies that make superb compression pads usually present little thermal resistance, and vice versa.

Cells will swell as they age, and breathe as they undergo charge-discharge cycles. Compression pads soak up the ensuing cell motion. Swelling with age happens over prolonged time scales, however the respiration that happens over a short while interval must be absorbed by the cell-to-cell barrier with a view to preserve constant stress. Polyurethane and silicone foams are very efficient compression pads, however, as low-temperature supplies, they merely can’t stand up to thermal runaway conditions. They might delay thermal propagation a bit, however hardly ever sufficient to realize even the five-minute commonplace, and positively no more than that. A great barrier is a versatile materials that’s additionally able to withstanding excessive temperatures. These two attributes—flexibility and high-temperature tolerance—are sometimes mutually unique.

Determine 2 exhibits potential cell-to-cell barrier supplies, with the Y-axis representing the utmost publicity temperature {that a} materials can stand up to and the X-axis indicating how a lot pressure vitality a fabric can soak up. The correct-hand facet of the graph exhibits that supplies generally used as compression pads, resembling silicone foams and polyurethane, can soak up a whole lot of pressure vitality, however their temperature tolerances max out round 100-300° C. On the left facet of the graph, we see that metals and mica sheets are very immune to excessive temperatures, however aren’t good at absorbing mechanical vitality. The Holy Grail of barrier supplies would reside within the upper-right nook of the graph, offering warmth resistance 5 instances higher than silicone foam and mechanical absorption 4 orders of magnitude above that of mica sheets. In accordance with Williams, Aspen Aerogels’ PyroThin suits the invoice.

“The universe of potential issues that may stay in that neighborhood may be very, very small,” mentioned Williams. “Certainly one of them is an aerogel resembling our PyroThin, which is engineered particularly to be a unitary materials inside a cell-to-cell barrier, offering each the mechanical operate of a compression pad and the thermal operate of a hearth barrier.”

Aspen Aerogels has been within the aerogel enterprise for greater than 20 years, primarily targeted on optimizing vitality effectivity and passive hearth safety for industrial vitality services. The corporate is now transferring its expertise to the EV phase, with the aim of creating the world’s greatest cell-to-cell limitations. Aspen’s testing exhibits {that a} two-millimeter sheet of PyroThin materials can stand up to publicity to a propane torch at 1,000° C, and soak up the pressure vitality from cell respiration and swelling. Williams claims that Aspen’s aerogels are the thinnest insulating supplies out there, and that they provide the very best thermal insulation properties.

It’s the chemistry

An aerogel is produced when complicated polymer chains of silica molecules type by a sol-gel course of. This course of is just like making gelatin, however utilizing silica and ethanol as an alternative of sugar and water. A moist part of suspended silica begins out with the viscosity of water; in about two minutes, the suspension turns gelatinous. Within the course of, the silica self-assembles into lengthy polymeric chains, which home tiny nano-pores.

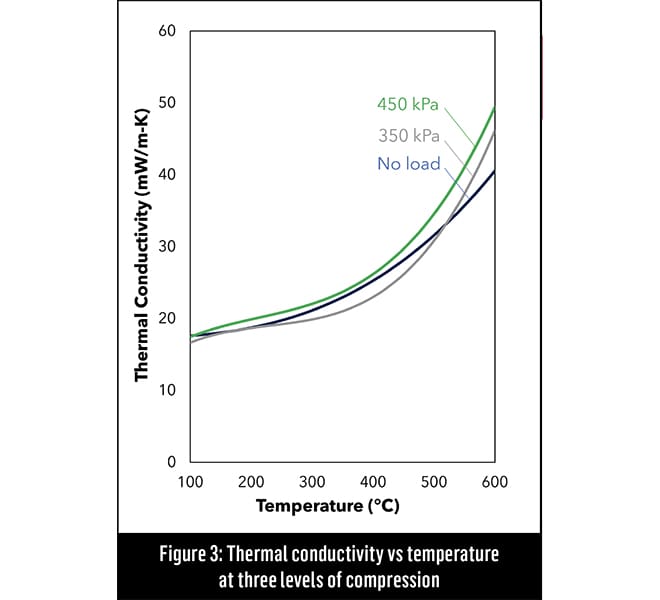

“An aerogel’s pores are 10,000 instances smaller than that of some other insulation materials. In that 4 orders-of-magnitude distinction, the physics fully modifications.”

“That nano-porosity is the key in an efficient thermal insulation materials,” mentioned Williams. “An aerogel’s pores are 10,000 instances smaller than that of some other insulation materials. In that 4 orders-of-magnitude distinction, the physics fully modifications. Now you will have a fabric that has a thermal conductivity decrease than nonetheless air, which implies that if you compress it and squeeze out the air, the thermal conductivity can truly get higher, [see Figure 3]. Underneath the identical circumstances, virtually each different insulation materials will worsen.”

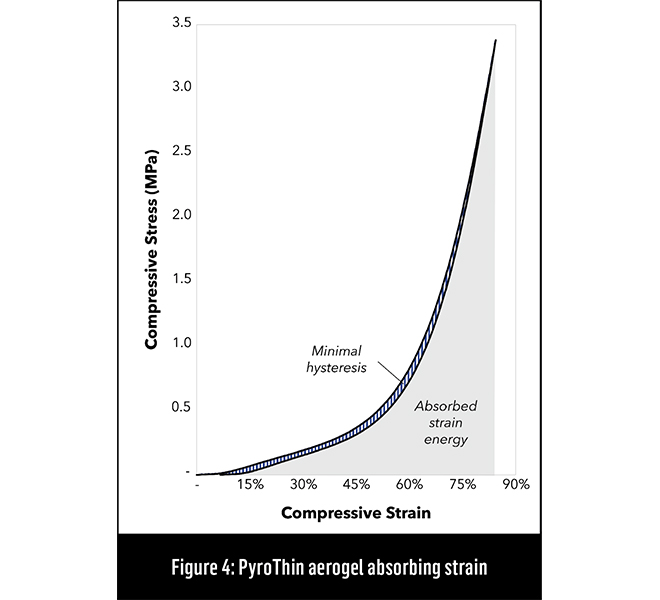

Determine 4 exhibits the connection between compressive stress and pressure—the realm beneath the curve represents the quantity of pressure vitality the fabric can soak up reversibly. Williams says that Aspen’s newer M-grade supplies will proceed to soak up pressure vitality over the lifetime of a car with minimal compression set or fatigue.

Actual-world testing

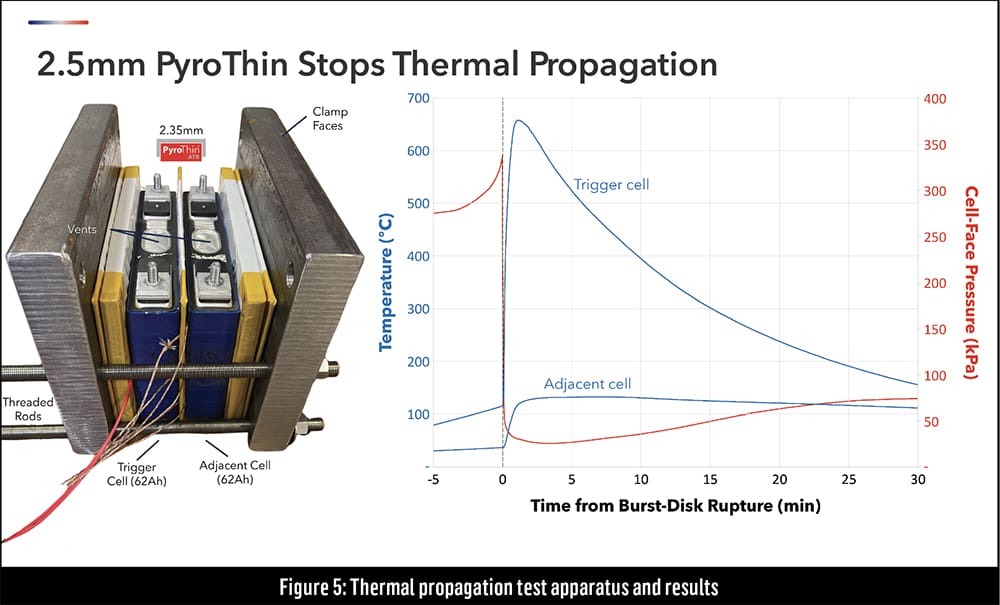

To check how supplies behave throughout a thermal occasion, Aspen’s engineers topic the supplies to mini-module testing. For instance, they put a thermal barrier between two cells and triggered one cell with a heating pad to see if the barrier would stop thermal propagation from one cell to the opposite.

The check setup in Determine 5 consists of two off-the-shelf prismatic cells compressed within a jig, permitting the experimenters to regulate the cell-face stress. The stress on the finish of a cell’s life tends to be larger than originally of its life, so Aspen conducts a worst-case state of affairs check by artificially creating larger stress contained in the jig. The graph on the precise exhibits that the elevated temperature of the set off cell (proper) is absorbed by the barrier materials, protecting the temperature of the adjoining cell (left) at a secure stage.

This mini-module experiment has limitations, nonetheless. In an actual battery pack, different pathways—secondary conduction, sizzling particulates and convection—additionally have an effect on the system. This check merely demonstrates that thermal runaway might be stopped on the cell-to-cell stage, permitting designers to concentrate on isolating the opposite mechanisms.

PyroThin has about the identical density as urethane foam, however the latter isn’t a thermal barrier. Urethane foam coupled with a thermal barrier will sometimes be heavier than a comparable half that’s made with PyroThin alone. As a result of PyroThin is each lighter and thinner than different thermal/mechanical limitations, battery designers can pack extra cells into the identical house, rising car vary.

Different cell packages and battery chemistries

Aspen concentrates on Li-ion cells in prismatic and pouch packages as a result of the aerogel materials naturally lends itself to flat, rectangular objects. In cylindrical cells, the interstitial house is much more complicated, so different supplies could carry out higher than PyroThin as cell-to-cell limitations. In these conditions, Williams says that PyroThin remains to be appropriate for pack covers, sidewall covers and different flat geometries.

A few of the firm’s clients have efficiently used PyroThin with lithium-metal batteries, which are inclined to burn hotter than Li-ion cells, typically reaching 1,200 to 1,400° C. Lithium-metal batteries make use of completely different grades of PyroThin, relying on the temperature requirement.

Apsen’s clients embody Basic Motors, which has chosen PyroThin because the cell-to-cell barrier for Ultium, the modular battery and drivetrain platform that may energy greater than 30 new EV fashions.

Partnerships

Aspen Aerogels presently presents consulting companies by its world engineering help staff, which incorporates engineers in Asia, Europe and North America who will reply questions on battery pack and barrier designs. The corporate’s clients embody Basic Motors, which has chosen PyroThin because the cell-to-cell barrier for Ultium, the modular battery and drivetrain platform that may energy greater than 30 new EV fashions.

To be taught extra about thermal limitations, take a look at the recording of Aspen Aerogel’s presentation on the Charged Digital Convention.

Don’t miss John Williams’ subsequent webinar on April 19, 2023:

Balancing Inner Forces Inside An EV Battery Module Or Pack

This text appeared in Concern 63: Jan-Mar 2023 – Subscribe now.

[ad_2]