[ad_1]

Continental has been setting requirements for higher sustainability with its retreading of truck tires since 1903. The premium tire producer has been utilizing retreading to increase the service lifetime of tires for greater than 120 years – conserving sources and lowering prices. Continental retreads multiple million truck and bus tires worldwide yearly. In keeping with a examine by the Fraunhofer Institute for Environmental, Security and Power Know-how (UMSICHT), retreaded tires cut back CO2 emissions by as much as 50 % in comparison with new tires. The quantity of recycled and renewable supplies in retreaded tires will be as much as 85 %. By way of traction, grip and security, retreaded tires from Continental are each bit a match for brand spanking new tires.

“We’ve been a pioneer in retreading truck and bus tires for greater than 120 years,” explains Jorge Almeida, Head of Sustainability at Continental Tires. “Our tire retreading saves uncooked supplies and prices – an actual win-win state of affairs for fleet operators and the surroundings.”

Turning previous into new: cold and hot retreading

Amongst different issues, tires encompass a casing and tread. Nonetheless, the casing should be fully intact, whereas the tread has reached the tip of its service life. Roughly 70 % of truck and bus tires had been thought of retreadable in 2022, primarily based on trade experiences and research of tire manufacturing practices.

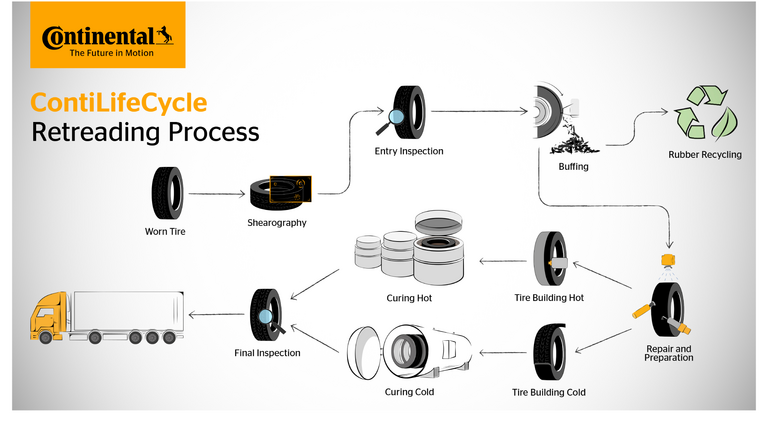

As a part of the retreading course of, the remaining tread rubber and, within the case of sizzling retreading, the sidewall of the tire are buffed and restored. This prepares the casing for a second and third tire life. Continental makes use of state-of-the-art evaluation processes, manufacturing strategies and recycling applied sciences in its cold and hot retreading. In sizzling retreading, the casing is restored from bead to bead in a sizzling vulcanization course of. A brand new rubber compound is utilized to the used casing. At Continental, this course of is named ContiRe. In chilly retreading, often known as ContiTread in Continental’s product vary, a profiled and pre-vulcanized tread materials is utilized to the buffed casing. Chilly retreading is carried out at decrease temperatures and with pre-vulcanized treads. Typically, round 70 % of the fabric from the unique tire will be reused in each cold and hot retreading.

From recovering reclaimed rubber to the absolutely built-in ContiLifeCycle plant

The origins of Continental’s tire retreading actions will be present in Hanover. Tires may already be retreaded on the Continental plant in Hannover-Vahrenwald greater than 120 years in the past. In 1903, the corporate additionally purchased a manufacturing unit constructing in Seelze within the Hanover area and arrange a plant on the positioning for reclaiming, i.e. processing and recycling previous rubber. Even again then, 9 to 13 tons of used rubber had been processed on daily basis. That’s equal to the common weight of round eight automobiles. Continental was already laying the foundations for round and sustainable enterprise again then.

Continental set one other necessary milestone within the retreading of truck tires in 2013 when it opened the ContiLifeCycle plant within the Stöcken district of Hanover. The distinctive function of this plant is its mixture of a retreading and a recycling plant. With an built-in method consisting of sizzling retreading for truck and bus tires in addition to a rubber recycling system developed particularly for the ContiLifeCycle plant, the corporate has been actively selling the sustainable use of uncooked supplies, water and power for a decade. Since 2013, round 900,000 truck and bus tires have been given an prolonged service life by way of retreading on the plant in Hanover-Stöcken. Since opening ten years in the past, round 900,000 truck and bus tires have been given an prolonged service life by way of retreading on the plant in Stöcken, Hannover.

Added worth for fleet clients

Retreaded tires additionally contribute to Continental’s LODC-concept, which is specifically designed for car fleets. “LODC stands for Lowest General Driving Prices, which is our complete consultancy method that seeks to assist fleet clients to cut back their tire-related operational prices,” explains Tansu Isik, Head of Area South, Channels Fleet and OE Trailer for Continental Tires EMEA. The sustainable ContiLifeCycle idea is an integral a part of our LODC method, providing fleet clients cold and hot retreaded tires, service-oriented casing administration together with ContiCasingAccount in addition to sturdy and fuel-saving new tires. “With our ContiRe and ContiTread retreads, fleets can cut back their tire prices by as much as 35 %, with a considerably decrease environmental influence,” Isik explains.

Increasing the round financial system

The retreading actions are an instance of Continental’s clever round financial system options. The surroundings advantages from retreading, as the usage of helpful sources resembling crude oil, pure rubber and water will be considerably lowered. As well as, retreading helps to save lots of CO2 emissions, because it requires as much as 70 % much less power in comparison with the manufacturing of a brand new tire. The truth that a big proportion of the casing will be reused contributes to the associated fee effectivity.

Continental is working tirelessly to advance modern applied sciences and sustainable services and products all through its total worth chain, from sourcing sustainable supplies to recycling end-of-life tires. The corporate additionally depends on the pyrolysis of used tires. The general objective is to recuperate 60 % of the supplies utilized in tire building from used tires by 2050 on the newest.

Retreading course of for truck and bus tires

SOURCE: Continental

[ad_2]