[ad_1]

Sponsored by Marposs.

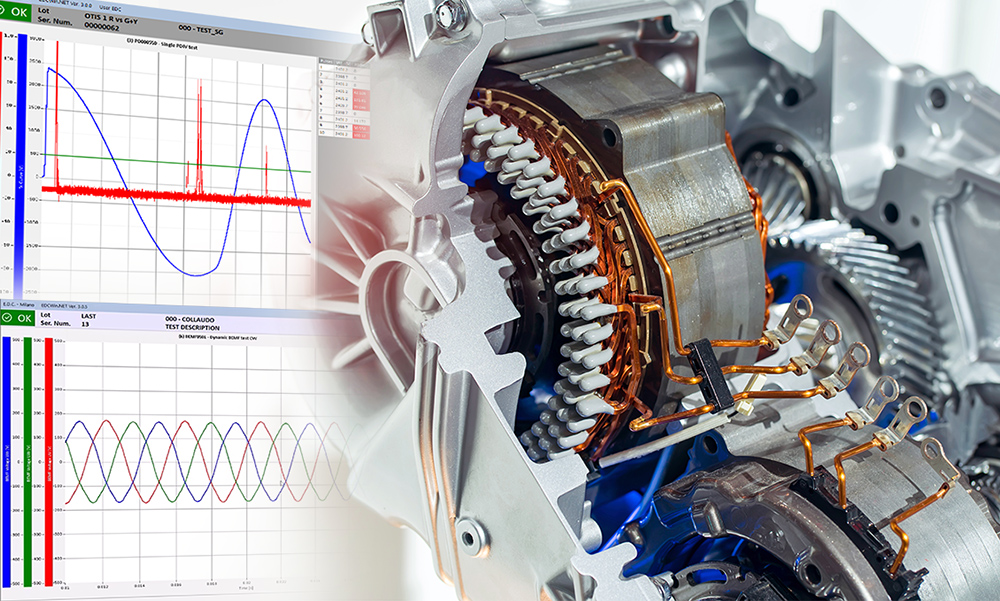

Motor testing is designed to test the integrity of an electrical motor by way of the usage of tools that identifies potential points inside the motor. The principle goal of motor testing is to disclose latent issues and to forestall pointless failure by evaluating static parameters like insulation, wire injury and electrical present leakage, in addition to extra dynamic parameters.

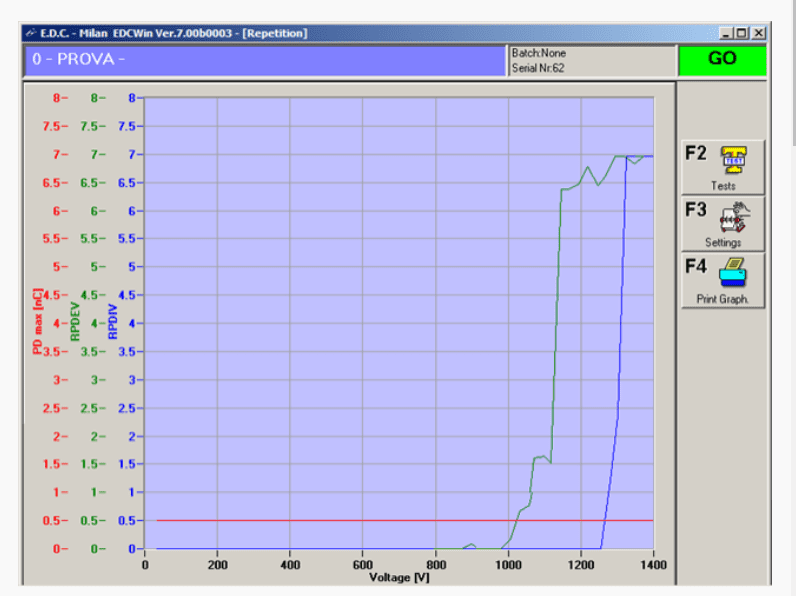

The insulating system {of electrical} machines is important to reliability since an insulation failure might lead to a system breakdown. Normal electrical assessments at present required by rules are unable to establish all kinds of failure. It’s because many defects produce solely partial discharges and these can solely be recognized utilizing the partial discharge check technique. This doesn’t exchange the usual assessments however needs to be carried out as well as.

Partial discharge measurements enable detection ofall latent defects that would generate failures in e-motors, after quick working instances. That is much more true for electrical motors powered by Inverter – like electrical autos – which, because of the inevitable voltage overshooting, causes extra stress to the motor windings.

A typical fault that happens, as an illustration, is when a wire touches the stack of the stator. If the enamel of the wire is scratched within the contact level with the stack, even the usual AC Hello-Pot check is can establish the fault. However, as generally occurs, if the wire is effectively insulated, the voltage utilized throughout the AC Hello-Pot Take a look at, even when fairly excessive, will not be enough to interrupt the remaining insulation materials and this fault will not be recognized. If the measurement of partial discharges is carried out similtaneously the AC Dielectric Power Take a look at then 100% of those defects are all the time recognized and filtered.

The consequence of everlasting partial discharges is a gradual but steady weakening of the practical components of the insulation system. This leads to an entire breakdown and failure of the electrical motor. That’s the reason it’s essential that there not be a partial discharge within the electrical motor throughout operation. And, that’s the reason the Marposs e.d.c. partial discharge testing technique is valued by automotive producers and Tier 1 suppliers.

The Marposs e.d.c. Partial Discharge Measurement System is predicated on capacitor coupling know-how. As in comparison with antenna-type options usually utilized on this market, the capacitor coupling approach is extra subtle and fewer delicate to exterior noise and, subsequently, extra appropriate for purposes within the manufacturing space. Because it doesn’t use any exterior sensor, the coupling capacitor strategy requires tools that may detect the partial discharge simply by connecting the terminals of the product underneath check with the identical cables used to carry out all different assessments (winding resistance, AC Excessive Pot assessments, Surge Assessments, and many others.)

With the e.d.c. merchandise, Marposs affords an entire vary of options devoted to the practical testing and the end-of-line testing of any kind of electrical motor, for in-line and off-line purposes or for laboratory evaluation and characterization.

Marposs supplies personalized inline and offline options for all electrical assessments and detection of insulation issues in any respect phases of growth and manufacturing of an e-motor and their elements, akin to:

As e-mobility continues to quickly develop, car producers, in addition to end-users, have to be assured within the reliability of the car performance. As such, partial discharge measurement testing performs an important function as an ordinary testing course of for electrical motor producers.

e.d.c. programs make use of partical discharge measurement know-how to establish 100% of latent defects and may be configured for stators, rotors, superior windings, finish of line assessments.

The e.d.c. partial discharge testing technique is predicated on Capacitor Coupling know-how that’s extra strong in relation to electromagnetic noise and consequently extra appropriate in comparison with Antenna technique for the use within the manufacturing atmosphere

Custom-made EoL testing system for fully assembled e-motor to be built-in inline or offline for operator use. Design-to-order check benches can be found for all types of rotors: Again EMF evaluation for everlasting magnets rotor, identification of defects of the cage bars for squirrel cage rotor.

Sponsored by Marposs.

[ad_2]